Bullet and blast resistance

Trusted by some of the most security-sensitive organizations in the world, we’re proven experts in blast-resistant building design. We use highly specialized materials tested by the National Institute of Justice (NIJ), HP White, and Underwriters Laboratory (UL), B.I.G. to achieve the industry’s highest level of blast resistance. Outfit your security booth with advanced bullet-resistant technology for superior and reliable protection. Our security guard design experts can discuss the benefits of the following safety measures: UL, NIJ, MIL-A-46100 Level 1 through 10 Transaction drawers Transaction trays Gun ports Interior and exterior intercom Hardening of floors and hatches Hardening of air conditioners and other options Blast resistance

State-of-the-art industrial paint process

Prior to painting each guard booth undergoes a Zirconization cleaning process, to ensure maximum paint adherence. This cleaning process helps our products to achieve the highest ASTM B117N standards available. Our industrial paint process includes a two-part epoxy rust inhibitor prime coat and a top-coat of two-component polyurethane, ensuring years of protection.

Steel track window system

There are only two moving parts to a guard booth; sliding doors and transaction windows. Some manufacturers use a traditional system that proves inadequate for long term use. Our system uses steel tracks, four steel ball bearing wheels, and the highest quality products available to take on the continuous use and abuse that doors and windows must endure. All booth building units have a steel window frame system with flush-mounted corners and welded fastening. Each unit will have fixed or operable windows on all sides, and all windows will be glazed with 1/4" tinted tempered glass. Exterior painted galvanized steel window frames are architecturally superior to aluminum, more durable, and offer easier glass replacement. Most states with energy codes will require the units to have ¾" minimum tempered dual pane insulated glass with Low-E coating. We recommend every exterior installation have this glass for better heating\cooling gain or loss.

Floor System

The 12-gauge galvanized steel plate floor is welded to a 2" galvanized steel tube floor frame and joists. This floor system is covered with black polyvinyl chloride interlocking tiles and a 4" base cove. We then weld 1/4" steel anchor plates to the floor frame's interior side with pre-drilled holes for anchoring the unit. Floors will have all the required cutouts for electrical, data & communication stub-ups.

Frame

Our building frame for standard booths is 2" x 2" x .083", and 3" x 3" x .083" for ballistic booths. Booth framing is cold drawn, electric welded structural mechanical steel and can withstand a wind load up to 220mph.

Roof

Our standard booth roof is all-steel and insulated to R-19 with a three-part Energy Star membrane coating that has a Solar Reflective Index (SRI) of 95 or greater. Our roofs are available in various styles, including flat roof, true standing seam, gable, and barrel-dome. We will also customize a style that best meets your location aesthetics. Roofs will have a fascia or overhang, as indicated on the drawings, and will be designed to drain through a gutter system with downspouts (if applicable). All booths with roof dimensions of 6' x 8' or larger have removable lifting eyes for hoisting by crane. Certain states require higher roof insulation, and we know each state's codes.

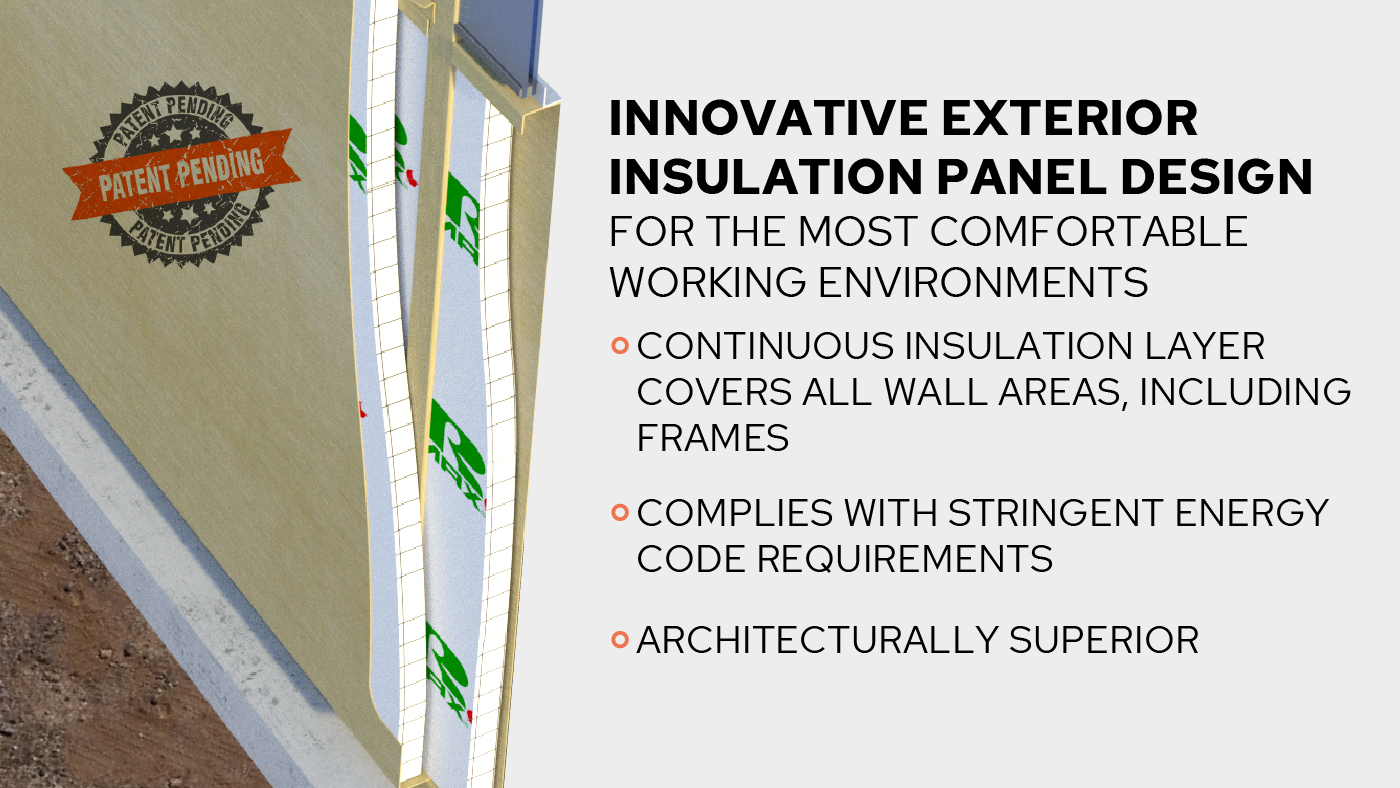

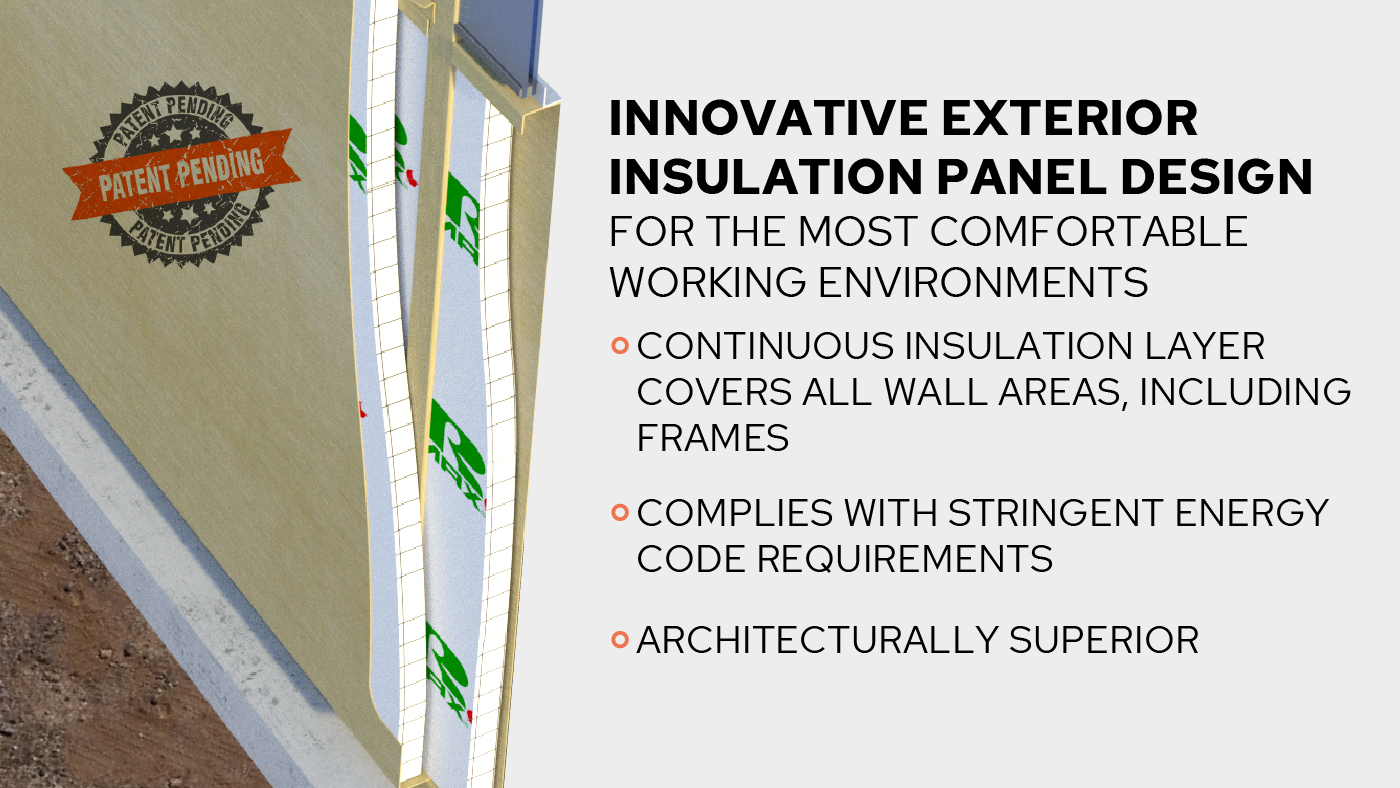

Wall system

We offer the industry’s only “standard” double-wall insulation system, consisting of 16-gauge cold-rolled galvanized steel panels on the interior and exterior panels with a minimum R-9.6 in-wall insulation, and another exterior continuous layer of R-9.6 insulation encapsulated in the final exterior 16-gauge steel panels. They are MIG welded between frames and mullions, creating a self-aligning, unitized structural diaphragm. In-wall insulation may vary, depending on installation location. In workplaces requiring high-security levels, guard enclosures can be constructed of blast-resistant and bulletproof materials.

Doors

Booth building will feature a heavy-duty steel framed sliding door constructed of steel tube frames and insulated 16 gauge galvanized steel panels. The door will be hung by a minimum of eight 2 1/4" steel ball bearing rollers in a steel upper track with a lower stainless steel guide. Doors will also feature stainless steel pull handles welded to the frame and mortise hook bolt lock. Steel doors are more durable and standard for all security guard booth specs. B.I.G. is the exclusive provider of the rigid steel ball-bearing roller system with welded stainless steel pull handles and stainless steel lower guide. Our doors are more aesthetically pleasing and offer years of maintenance use.

Steel track window system

There are only two moving parts to a guard booth; sliding doors and transaction windows. Some manufacturers use a traditional system that proves inadequate for long term use. Our system uses steel tracks, four steel ball bearing wheels, and the highest quality products available to take on the continuous use and abuse that doors and windows must endure. All booth building units have a steel window frame system with flush-mounted corners and welded fastening. Each unit will have fixed or operable windows on all sides, and all windows will be glazed with 1/4" tinted tempered glass. Exterior painted galvanized steel window frames are architecturally superior to aluminum, more durable, and offer easier glass replacement. Most states with energy codes will require the units to have ¾" minimum tempered dual pane insulated glass with Low-E coating. We recommend every exterior installation have this glass for better heating\cooling gain or loss.

Conduits & boxes

In addition to the standard booth design conduits and boxes, booth building units will have empty 2" x 4" J-Boxe(s) mounted under the shelf with 1/2" empty conduit runs and a pull string to the stub area for data and communication lines by others. This design provides an easy pathway for typical items added to customized guardhouses on site.

Electrical system

The standard booth design for the electrical system will have all U.L. approved fixtures wired to N.E.C. standards. Units shall have interior LED light(s) recessed in a 16 gauge galvanized steel ceiling painted to match the booth interior color and controlled by a single-pole wall switch, dimmer switch, or occupancy sensor. The unit will also have a 20 amp duplex outlet receptacle mounted under the shelf. All items will be wired to 125 Amp rated, 120/240 volt, 12 pole, 3 wire single phase load center.

Booth insulation process

Our latest design innovation is our BIGtherm booth insulation process. We add a continuous insulation layer within our exterior galvanized steel panel, enveloping the entire booth and encapsulating the structural frames as well. This process is used in all our booths - both Non-Bullet Resistant and Bullet-Resistant. This process delivers superior thermal performance, even in extreme cold and hot climates.

HVAC

We design guardhouse HVAC systems to ensure year-round comfort for your guards and staff to keep them performing at their best. Our options include: Wall-mounted heat pump, Split system wall aesthetic treatments, Roof mount, High output heaters, Combination systems, Baseboard heaters, Ventilators, Passive / powered, Louvers, Thermostat controls, Exhaust vents, Ceiling vent fans.

HVAC

Cabinets & drawers

Premium storage space featuring quality materials and fine craftsmanship. Our options include: Stainless Steel Custom commercial cabinet (to your design) Cash drawers Currency transfer Floor safe Wall mounted safe Drop safe Class B safes (or to specification)

Security Desk Organization

At B.I.G. we know how to manufacture guard booths. So at the final installation, Security Consoles and Monitors fit perfectly and are well organized. Work with our Expert Sales & Engineering team to have your booth manufactured the right way.

Bullet and blast resistance

Trusted by some of the most security-sensitive organizations in the world, we’re proven experts in blast-resistant building design. We use highly specialized materials tested by the National Institute of Justice (NIJ), HP White, and Underwriters Laboratory (UL), B.I.G. to achieve the industry’s highest level of blast resistance. Outfit your security booth with advanced bullet-resistant technology for superior and reliable protection. Our security guard design experts can discuss the benefits of the following safety measures: UL, NIJ, MIL-A-46100 Level 1 through 10 Transaction drawers Transaction trays Gun ports Interior and exterior intercom Hardening of floors and hatches Hardening of air conditioners and other options Blast resistance

Security Desk Organization

At B.I.G. we know how to manufacture guard booths. So at the final installation, Security Consoles and Monitors fit perfectly and are well organized. Work with our Expert Sales & Engineering team to have your booth manufactured the right way.

Restroom facilities

Built-in restroom facilities offer your employees quick access to a restroom when needed. This adds to employee comfort and improved productivity. We can frame out a space, or we will install a restroom that is compliant with all regulations for people with disabilities. Other options include commercial wall mount systems, and compost or incinerator toilets.